Abakhiqizi bahlinzeka ngephampu yegiya ye-automation machine hardware hydraulic gear pump

Incazelo Yomkhiqizo

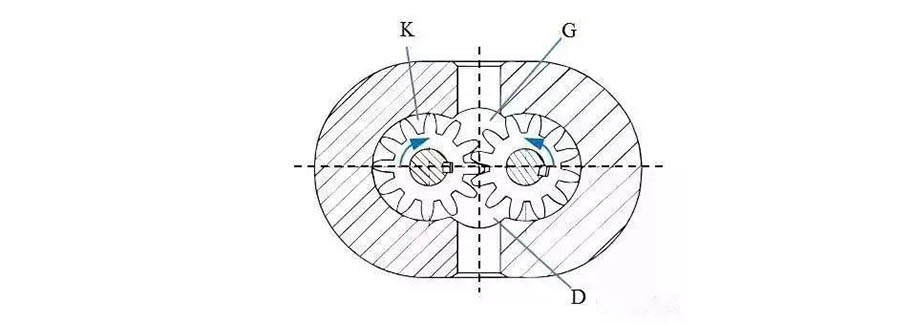

Isilinda esiphezulu sezinyo kanye nobuso bokugcina kuzo zombili izinhlangothi zepheya lamagiya ahlanganayo asondelene nodonga lwangaphakathi lwekheshi yepompo, futhi uchungechunge lwezimbotshana zokusebenza ezivaliwe K zivalelwe phakathi kwesikhala sezinyo ngasinye kanye nodonga lwangaphakathi lwebhokisi. Izimbobo ze-D kanye ne-G ezihlukaniswa ngamazinyo egiya eline-meshing yigumbi lokumunca kanye negumbi lokukhipha elixhunywe nembobo yokudonsa kanye nembobo yokukhipha yepompo, ngokulandelanayo. Njengoba kubonisiwe (i-meshing yangaphandle).

Lapho igiya lizungeza lapho elikhonjiswe khona emfanekisweni, ivolumu yegumbi lokuncela D kancane kancane ikhula futhi ingcindezi iyehla ngenxa yamazinyo egiya eline-meshing aphuma kancane kancane kusimo se-meshing. Ngaphansi kwesenzo somehluko wengcindezi phakathi kwengcindezi ye-liquid surface yechibi lokudonsa kanye nengcindezi ephansi ku-cavity D, uketshezi lungena egunjini lokudonsa D lisuka echibini lokudonsa ngepayipi lokumunca kanye nembobo yokudonsa yepompo. Bese ingena endaweni yokusebenza evaliwe engu-K, bese ilethwa egunjini lokukhipha u-G ngokujikeleza kwegiya. Ngenxa yokuthi amazinyo amagiya amabili angena kancane kancane endaweni ye-meshing esuka ohlangothini olungaphezulu, amazinyo egiya elilodwa kancane kancane athatha indawo yokugoqa elinye igiya, ukuze umthamo wegumbi lokukhipha elitholakala ohlangothini olungaphezulu wehle kancane kancane, futhi ingcindezi yoketshezi ekamelweni iyanda, ngakho-ke iphampu ikhishwa epompo. Imbobo yokukhipha ikhishwa ngaphandle kwepompo. Igiya lijikeleza ngokuqhubekayo, futhi izinqubo ezibalwe ngenhla zokumunca nokukhipha zenziwa ngokuqhubekayo.

Indlela eyisisekelo kakhulu yephampu yegiya ukuthi amagiya amabili anosayizi ofanayo anezikhala futhi azungezisane kwelinye kukesi efakwe ngokuqinile. Ingaphakathi le-casing lifana nesimo "8", futhi amagiya amabili afakwe ngaphakathi. Indlu ilingana kahle. Izinto eziphuma ku-extruder zingena maphakathi namagiya amabili echwebeni lokudonsa, zigcwalise isikhala, zinyakaze eduze kwe-casing ngokuzungezisa amazinyo, futhi ekugcineni ziyaphuma lapho amazinyo amabili ehlangene.

Izici

1.Ukusebenza okuhle kokuzenzela.

2. Isiqondiso sokudonsa nokukhishwa sincike ngokuphelele ekuqondeni kokujikeleza kwe-pump shaft.

3. Izinga lokugeleza kwepompo alilikhulu futhi liqhubekayo, kodwa kukhona ukushaya futhi umsindo mkhulu; izinga lokushaya ngamandla li-11%~27%, futhi ukungalingani kwalo kuhlobene nenani nokuma kwamazinyo egiya. Ukungalingani kwamagiya e-helical kuncane kunalawo amagiya e-spur, futhi umuntu Ukungalingani kwegiya le-helical kuncane kunalokhu kwegiya le-helical, futhi uma isibalo samazinyo sincane, sikhulu izinga lokushaya.

4. Ukugeleza kwethiyori kunqunywa ubukhulu nesivinini sezingxenye zokusebenza, futhi akuhlangene nokucindezela kokukhipha; ukucindezela kokukhishwa kuhlobene nokucindezela komthwalo.

5. Isakhiwo esilula, intengo ephansi, izingxenye ezimbalwa zokugqoka (asikho isidingo sokusetha i-valve yokumunca nokukhipha), ukumelana nomthelela, ukusebenza okuthembekile, futhi kungaxhunywa ngokuqondile ne-motor (asikho isidingo sokusetha idivayisi yokunciphisa).

6. Kunezindawo eziningi zokungqubuzana, ngakho-ke akufanelekile ukukhipha uketshezi oluqukethe izinhlayiya eziqinile, kodwa ukukhipha uwoyela.